-

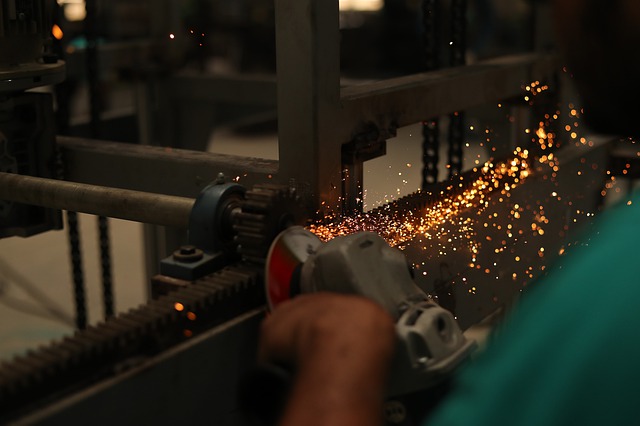

The manufacturing sector recorded a slight expansion in September 2021, the highest since March, with easing of COVID-19-related restrictions and resumption of some businesses

-

The Philippine Purchasing Managers’ Index rose from 46.4 in August to 50.9 in September

-

The latest index is marginally above the 50.0 no-change threshold that separates expansion from contraction

-

Supply chains continued to be impacted by international COVID-19 restrictions during September, with reports of port congestion, freight delays and container shortages

-

The key drivers of rising costs included raw material scarcity, container shortages, higher shipping fees and unfavorable exchange rate movements

The Philippine manufacturing sector recorded a slight expansion in September 2021, the highest since March, as some COVID-19-related restrictions eased and businesses resumed operations.

The Philippine Purchasing Managers’ Index rose from 46.4 in August to 50.9 in September, slightly above the 50.0 no-change threshold that separates expansion from contraction.

Although only marginal, the latest uptick was the strongest since March, according to the latest survey of London-based IHS Markit.

“After a tough trading period in August, manufactures in the Philippines welcomed the relaxation of some virus-related restrictions,” IHS Markit economist Shreeya Patel said, adding that a number of factories and businesses resumed operations.

Production volumes, however, fell during September, marking a six-month sequence of decline. Firms continued to indicate that the remaining COVID-19 restrictions hampered production.

Similarly, new orders declined further, but at a softer pace during September. IHS Markit said anecdotal evidence revealed a general reluctance to spend among clients amid ongoing restrictions.

Meanwhile, after falling sharply in the previous survey period, there was broad stagnation in new export sales.

A combination of weak consumer demand, enhanced community quarantine measures, and voluntary resignation left manufacturing firms in the Philippines with lower staffing levels.

Despite the sustained period of job shedding, firms were able to keep backlogs at bay, as has been the case since March 2016.

Supply chains continued to be impacted by international COVID-19 restrictions during September.

In addition to the pandemic, there were reports of port congestion, freight delays and container shortages. Except for the marked decline seen in the previous survey period, lead times were extended to the greatest degree since August 2020.

In response to lengthy lead times, and in anticipation of greater client demand, firms raised their stocks of purchases, which followed a decline in August.

Post-production holdings fell for the second month in a row, but at only a marginal pace.

On prices, the key drivers of rising costs included raw material scarcity, container shortages, higher shipping fees and unfavorable exchange rate movements.

The rate of input price inflation moderated for the fifth month running, but was still quicker than the long-run series average. This, in turn underpinned an increase in selling charges as firms sought to pass on part of the burden.

Firms that lowered their selling prices mentioned efforts to encourage sales.

Business sentiment, meanwhile, was widely upbeat, and improved from August amid global vaccination efforts. Still, firms remained skeptical of the longer-term implications of COVID-19 with optimism historically subdued.