A new report released August 23, 2011 by a global business consulting service advises manufacturers to identify the risk areas they need to monitor to “protect and prepare their supply chain matrix against a ticking time bomb of financial instability.”

A new report released August 23, 2011 by a global business consulting service advises manufacturers to identify the risk areas they need to monitor to “protect and prepare their supply chain matrix against a ticking time bomb of financial instability.”

In its report, “Achieving Excellence in Production and Supply,” PricewaterhouseCoopers (PwC) pinpointed five key areas that the global manufacturing industry must address in today’s turbulent times:

- Identifying and preventing supply chain risks

- Linking demand planning with the whole value chain

- Making customer and supplier collaboration real

- Addressing life cycle opportunities and demonstrating sustainable value

- Attracting the people and skills needed for the future

“Supply chains and the manufacturing industry have been on a roller coaster ride, hit by skyrocketing prices of oil and commodities, high levels of debt, weak demand and tight credit,” said Barry Misthal, who heads PwC’s global industrial manufacturing group. “This report asks manufacturers if they have the right tools in place to adapt and prepare for potential future risks. The reality is many do not know who their high-risk suppliers are or where the cracks and loose chinks are in their supply chains.”

Misthal further said that with the current volatility of geopolitical, economic and financial markets, “businesses need to research their risk areas and mitigate where they can in areas such as life cycles, demand planning and skill shortages.”

The financial stability of suppliers will be one crucial factor affecting the industry, PwC said. If interest rates rise, for example, it will be much tougher for businesses to service loans. Firms will also need to work on attracting the right employees, who can be flexible and can adapt their skills to volatile situations.

The report stresses that the external collaboration between customers and suppliers needs to be matched with an internal culture change. As well as addressing shortages in STEM (science, technology, engineering and mathematics), businesses will need to build new, stronger workforces that can work together as a team and collaborate right across a supply chain.

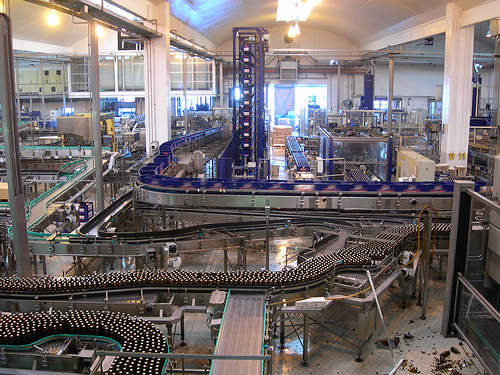

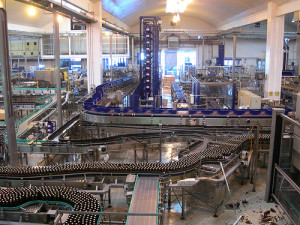

Photo by pickinjim2006